Views: 0 Author: Site Editor Publish Time: 2025-11-13 Origin: Site

As global demand for energy storage systems (ESS) continues to grow, thermal management has become

a critical challenge. Excessive heat not only reduces battery efficiency but also increases safety risks

such as thermal runaway and fire hazards. To address these issues, immersion cooling using dielectric fluids

has emerged as one of the most advanced and reliable solutions.

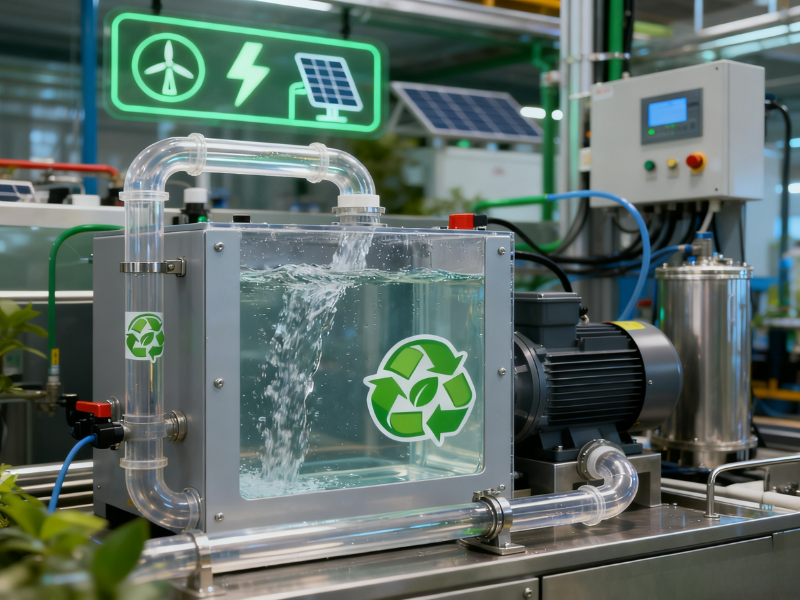

Immersion cooling is a thermal management technology that submerges battery cells or modules directly

into a non-conductive dielectric liquid. Unlike air or indirect liquid cooling, this method allows

for direct contact heat exchange, providing faster and more uniform temperature control across the system.

The dielectric cooling fluid acts as both an insulator and a heat carrier — efficiently transferring heat

away from active components while preventing electrical conduction or short circuits

One of the biggest concerns in large-scale energy storage systems is fire safety. Traditional cooling methods

often fail to manage localized overheating, leading to potential ignition. Dielectric immersion fluids,

on the other hand, are chemically stable and non-flammable, effectively reducing the risk of thermal runaway.

In addition, these fluids form a protective dielectric barrier, ensuring that even in case of system damage,

no short-circuit or electrical arcing occurs. This makes immersion cooling particularly suitable for lithium-ion

and LFP battery systems used in renewable energy storage, EV charging stations, and backup power applications.

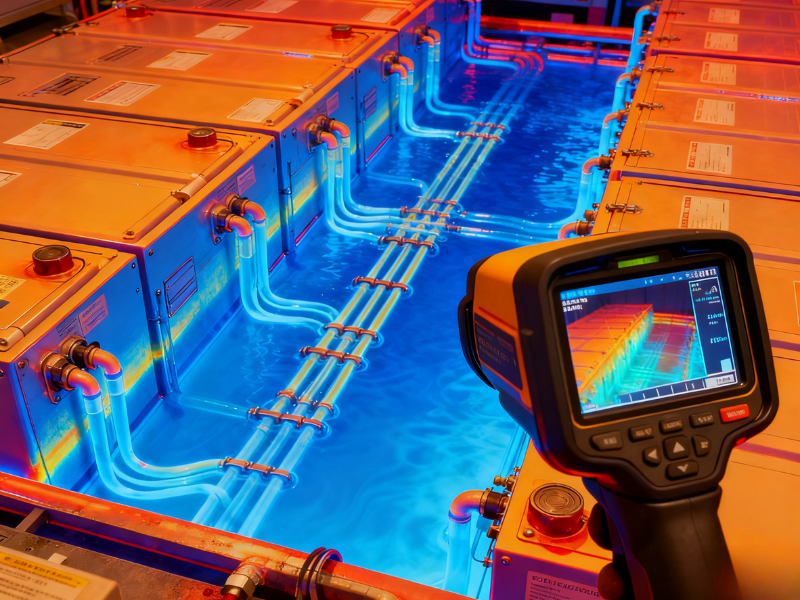

When battery modules operate, they generate heat at various points — cells, busbars, and interconnects.

In an immersion cooling system, the dielectric fluid circulates continuously, absorbing heat directly from the source.

The fluid then passes through a heat exchanger, where it releases the thermal load into a secondary coolant loop or ambient air.

This closed-loop thermal pathway allows for exceptional cooling uniformity, enabling batteries to operate at optimal

temperatures and extend cycle life by reducing thermal stress.

Modern dielectric fluids are engineered with low global warming potential (GWP) and zero ozone depletion potential (ODP).

Many are recyclable and have long service lifetimes, reducing maintenance costs and environmental impact.

Compared with traditional air or cold-plate systems, immersion cooling offers up to:

40–50% higher heat transfer efficiency

30% longer battery lifespan

Significant noise reduction and space savings

These features make dielectric cooling an ideal solution for the next generation of green energy storage systems.

Immersion cooling technology is increasingly used in:

Grid-scale energy storage systems (ESS)

Battery energy storage containers (BESS)

Renewable integration facilities (solar + storage / wind + storage)

EV charging stations and battery recycling hubs

Thermal energy storage in data centers

As energy systems evolve toward higher power density and compact modularity, dielectric immersion cooling

provides both safety and scalability for large deployments.

In the coming decade, immersion cooling fluids will play a central role in transforming the safety, efficiency,

and sustainability of global energy storage. From data centers to battery containers, this technology offers

a path to smarter, cooler, and greener power systems.

At the core of this innovation lies one principle — the science of silence and safety in every drop.